Service Details

Diamond Core Drilling Equipment’s

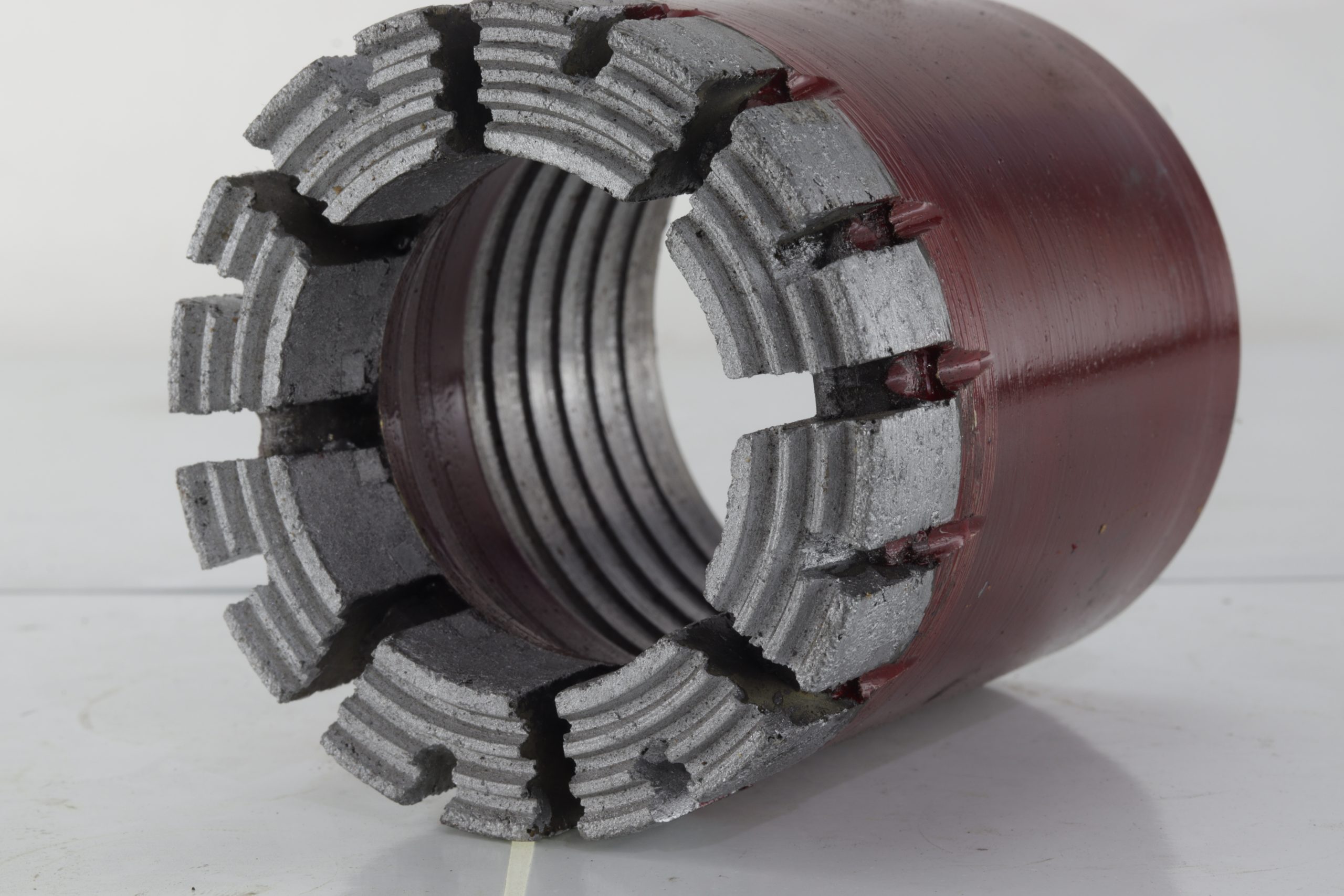

Core Drilling Bit Services – Surface Set, Impregnated & Reaming Shells Available in BQ, NQ, HQ, PQ, NQ3, HQ3, PQ3 Sizes We offer premium-quality diamond core drilling bits and accessories, built for high-performance mineral exploration, geotechnical investigations, and deep-hole drilling. Our products are designed to meet tough geological demands, ensuring longer life, faster penetration, and superior core recovery.

- Surface Set Diamond Core Bits

- Impregnated Diamond Core Bits

- Diamond Reaming Shells

- We manufacture and deliver TC (tungsten carbide) bits for overburden and soft formations.

- Custom bit designs tailored to your ground conditions and drilling requirements.

- Full range of reaming shells, casing bits, and core drilling accessories.

Complete Service Offer Details:

🔧 Products We Offer:

1. Surface Set Diamond Core Bits

-

Ideal for: Soft to medium-hard formations

-

Features:

-

Single-layer industrial diamonds hand-set on the crown.

-

High drilling speed with minimal torque.

-

Especially effective in formations with little abrasiveness.

-

2. Impregnated Diamond Core Bits

-

Ideal for: Medium to very hard and abrasive formations

-

Features:

-

Multiple layers of synthetic diamonds evenly distributed in a metal matrix.

-

Self-sharpening as the matrix wears.

-

Suitable for drilling in varied and unpredictable geology.

-

3. Diamond Reaming Shells

-

Purpose: Maintains borehole size, reduces vibration, stabilizes bit

-

Features:

-

Natural or synthetic diamonds bonded to a steel body.

-

Designed to match the bit diameter exactly.

-

Extends bit life and improves hole straightness.

-

⚙️ Manufacturing Process of Core Drilling Bits

Our in-house manufacturing follows strict quality protocols to deliver consistent results:

🔍 1. Geology-Based Design Consultation

-

Work with clients to determine ground conditions (abrasiveness, hardness, structure).

-

Recommend optimal bit crown profile, matrix grade, and waterway style.

✍️ 2. CAD Modeling & Toolpath Simulation

-

Engineers develop detailed 3D CAD models for each bit.

-

Simulate cutting paths, fluid flow, and bit wear digitally before physical production.

⚖️ 3. Raw Material Selection

-

Source high-grade synthetic diamonds and powdered metal alloys.

-

Materials are graded by mesh size and hardness for consistency.

🌀 4. Powder Blending & Diamond Mixing

-

Precisely measured metal powder blends are mixed with diamond grit.

-

Mixing is performed in vacuum-sealed or inert gas environments to prevent contamination.

🔥 5. Cold Compaction (Preforming)

-

Powder-diamond mixture is pressed into a steel mold to form a pre-bit shape (preform).

-

Ensures even density and diamond dispersion.

♨️ 6. Hot Pressing / Sintering

-

Preforms are heated under high temperature (750–1,000°C) and pressure in a sintering press.

-

This bonds the matrix and diamonds into a single high-strength bit crown.

🧊 7. Controlled Cooling & Stress Relief

-

The bit crown is cooled slowly in a nitrogen atmosphere or inert chamber to prevent cracks.

-

Post-press heat treatments improve hardness and durability.

🛠️ 8. Surface Set Bit Diamond Embedding (Manual or Robotic)

-

For surface set bits, diamonds are manually positioned in patterns.

-

A high-silver content solder or brazing material is used to fix them in place.

🔩 9. Thread Machining & Body Fabrication

-

Bit bodies are CNC-machined to precise thread dimensions (BQ/NQ/HQ/PQ).

-

Runout and concentricity checks ensure perfect alignment with drill strings.

🔍 10. Precision Grinding & Waterway Finishing

-

Bit crown is ground to final shape and size.

-

Waterways are milled or EDM-cut for optimal flushing efficiency.

🧪 11. Rigorous Quality Control

-

Each bit undergoes:

-

Hardness testing (Rockwell)

-

Dimensional verification

-

Diamond exposure and distribution analysis

-

Balancing tests

-

Thread gauge inspections (GO/NO-GO standards)

-

🖌️ 12. Anti-Corrosion Coating & Final Packaging

-

Final bit is coated with protective anti-rust layers.

-

Laser engraved with size, matrix code, production batch, and part number.

-

Carefully packed for field-ready use.

🌍 Industries & Applications:

-

Mineral Exploration & Core Drilling

-

Geotechnical & Environmental Sampling

-

Mining Feasibility Studies

-

Infrastructure & Tunnel Boring Projects

-

Water Well and Hydrogeology Surveys

🔧 We Also Offer:

-

Custom bit development for challenging formations

-

Reaming shell refurbishing & re-tipping

-

Bit re-sharpening and matrix reconditioning

-

Thread repair and retooling

Website By : Dhanbad Developers