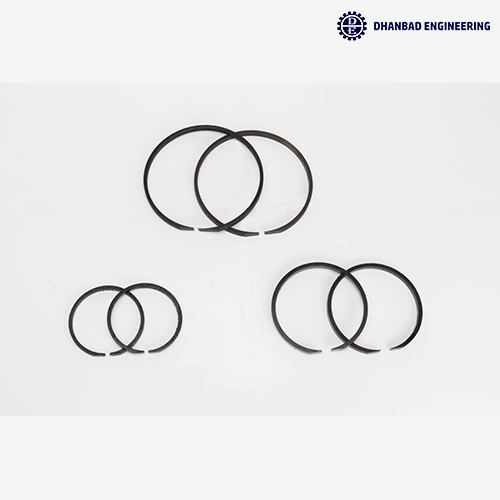

Stop Ring

Stop Ring – Precision Positioning Component for Core Drilling Assemblies

Enhance Alignment and Prevent Over-Travel in Wireline Core Drilling

Engineered for Mineral Exploration and Geotechnical Drilling Systems

✅ Product Overview:

The Stop Ring is a small yet vital component used in wireline core drilling systems to ensure the correct positioning of inner tube assemblies within the outer tube. It acts as a mechanical stop to prevent over-travel, ensuring the inner tube lands correctly and remains secure during the drilling process. The Stop Ring helps maintain consistent drilling depth, improves core recovery, and protects key components from misalignment or impact damage.

Ideal for mineral exploration, geotechnical investigations, and other core sampling activities, the Stop Ring is manufactured with high-precision tolerances and made from high-strength, wear-resistant materials to ensure reliability in harsh drilling environments.

Description

⚙️ Key Features:

-

🔒 Accurate Positioning: Ensures that the inner tube assembly is consistently aligned and properly seated within the outer tube.

-

🛠️ Prevents Over-Travel: Acts as a mechanical stop to prevent excessive inner tube movement, protecting against damage and misalignment.

-

🏗️ Heavy-Duty Construction: Made from hardened steel or alloy for long-lasting performance and resistance to deformation.

-

🌧️ Corrosion Resistant: Treated with a protective coating to withstand water, drilling fluids, and corrosive downhole environments.

-

🔧 Precision Machined: Built to tight tolerances for compatibility with standard NQ, HQ, PQ, and custom core barrel sizes.

-

🔄 Easy Replacement: Designed for quick installation and removal as part of routine core barrel maintenance.

📏 Specifications:

-

Material: High-strength alloy steel, optionally plated for corrosion resistance.

-

Size Options: Available for NQ, HQ, PQ, and other core barrel dimensions.

-

Weight: Lightweight yet robust, with optimized design for minimal wear.

-

Fitment: Precision fit with inner tube landing shoulder for consistent placement and long service life.

-

Finish: Smooth surface and treated for wear and corrosion protection.

🛒 Why Choose the Stop Ring?

-

✔️ Protects Core Barrel Integrity: Prevents misalignment and over-travel, protecting inner tube components.

-

✔️ Improves Core Recovery Consistency: Ensures precise inner tube placement, which supports accurate and uninterrupted core sampling.

-

✔️ Low Maintenance: Durable and long-lasting, designed for repeated use with minimal wear.

-

✔️ Field-Proven Design: Trusted by professionals in mineral exploration, geotechnical drilling, and environmental sampling.

-

✔️ Versatile Compatibility: Works with all major wireline core drilling systems.

Wireline drilling presents a specialized method for core removal. Unlike conventional core drilling, where the entire core barrel must be extracted from the hole, wireline drilling offers a more efficient alternative.

With wireline drilling, the process involves removing a barrel of core from the bottom of the hole without the need to extract the entire rod string. When it’s time to retrieve the core, an overshot is lowered with a wireline attached.

The overshot securely fastens to the back of the core barrel’s inner tube, and by retracting the wireline, the inner tube disengages from the barrel, facilitating swift and streamlined core retrieval