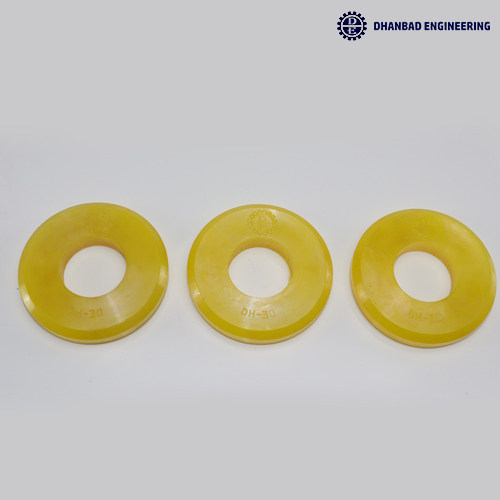

Shutoff Valve NQ

Shutoff Valve – Precision Fluid Control for Core Drilling Operations

Robust and Reliable Shutoff Valve for Drilling Fluid Management

Ideal for Mineral Exploration, Geotechnical Drilling, and Wireline Core Drilling

✅ Product Overview:

The Shutoff Valve is a critical component in core drilling systems, designed to control or stop the flow of drilling fluids—such as water, mud, or air—during drilling operations. It enhances safety, improves efficiency, and allows for quick isolation of fluid systems when needed. Installed between the water swivel and drill rod, the valve helps reduce fluid loss, manage pressure, and prevent backflow during equipment changes or maintenance.

Perfect for mineral exploration, geotechnical investigations, and wireline core drilling, the Shutoff Valve is built to withstand high pressure and corrosive environments, making it a must-have for fluid control in any drilling setup.

In diamond drilling operations, the NQ, HQ, and PQ shut-off valves stand as crucial components within the drill string. These valves play a vital role in regulating the flow of drilling fluid or mud, tailored to the specific sizes of drill rods used.

“NQ,” “HQ,” and “PQ” signify distinct sizes of drill rods

Description

⚙️ Key Features:

-

🚿 Precision Flow Control: Enables operators to start or stop drilling fluid flow instantly, providing greater control and minimizing fluid waste.

-

🛠️ High-Pressure Performance: Built to withstand high-pressure environments, typically rated for up to 10,000 psi.

-

🔄 Full Port Design: Allows unrestricted fluid flow, reducing pressure loss and improving flushing efficiency.

-

🔧 Easy Installation: Compatible with standard drill rod and swivel connections, enabling fast, hassle-free integration into existing systems.

-

🏗️ Heavy-Duty Construction: Made from high-strength steel or brass, with internal sealing components designed for long service life.

-

🌧️ Corrosion Resistant: Features a corrosion-resistant finish to withstand exposure to water and harsh drilling chemicals.

📏 Specifications:

-

Material Options: Hardened steel, stainless steel, or brass, based on application.

-

Pressure Rating: Typically available in 5K, 10K, and 25K psi variants.

-

Connection Type: Standard threads for compatibility with AW, BW, NW, HQ, or custom systems.

-

Seal Type: Internal O-ring or soft-seal technology to prevent leaks and backflow.

-

Flow Type: Full-bore design for unrestricted flow.

🛒 Why Choose This Shutoff Valve?

-

✔️ Enhanced Safety: Isolate fluid flow instantly to perform maintenance or equipment swaps without risking spills or blowouts.

-

✔️ Versatile Use: Works with a variety of drilling systems including core drilling, reverse circulation, and geotechnical rigs.

-

✔️ Low Maintenance: Built for long-term use with replaceable seals and components.

-

✔️ Durable and Reliable: Manufactured to handle extreme pressures and abrasive fluids, ensuring extended service life in the field.

-

✔️ Efficient Fluid Management: Prevents backflow, reduces mess, and improves flushing control for cleaner boreholes and better core recovery.

“In diamond drilling operations, the NQ, HQ, and PQ shut-off valves stand as crucial components within the drill string. These valves play a vital role in regulating the flow of drilling fluid or mud, tailored to the specific sizes of drill rods used.

“NQ,” “HQ,” and “PQ” signify distinct sizes of drill rods:

- NQ: Typically around 2.375 inches (60.3 mm) in diameter.

- HQ: Featuring a larger diameter, usually around 3.5 inches (88.9 mm).

- PQ: The largest of the three, with a diameter typically around 4.75 inches (120.6 mm).

Despite the differences in rod size, the shut-off valves associated with each perform similar functions, finely tuned to their respective diameters.

These valves offer several advantages:

- Flow Regulation: Allowing drillers precise control over drilling fluid or mud flow through the string, vital for maintaining optimal drilling conditions.

- Safety Measures: Promptly shutting off fluid flow enhances safety on-site, averting potential hazards or spills.

- Operational Efficiency: By ensuring precise fluid control, these valves bolster overall drilling efficiency, leading to smoother operations and heightened productivity.

In essence, the NQ, HQ, and PQ shut-off valves are indispensable elements, guaranteeing safety, efficiency, and control in diamond drilling operations across varying drill rod sizes.”