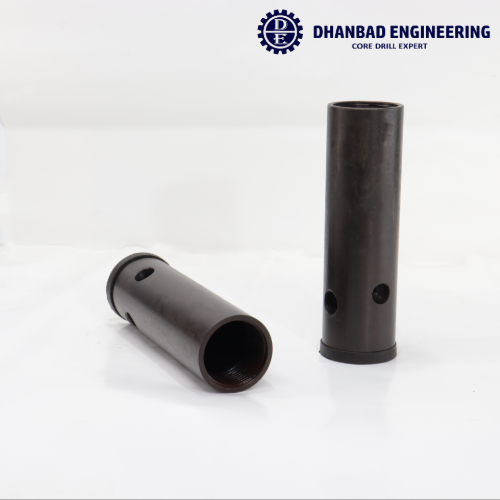

HQ INNER TUBE CAP

HQ Inner Tube Cap – Precision-Engineered Top-End Component for Wireline Core Barrel Systems

The HQ Inner Tube Cap is a vital top-end component of the wireline inner tube assembly used in diamond core drilling and mineral exploration. It serves as the protective upper closure of the inner tube, ensuring sealing integrity, precise component alignment, and smooth fluid circulation during drilling and core retrieval operations.

Designed for HQ wireline systems, this cap maintains the pressure balance inside the core barrel, preventing contamination and fluid leakage while securing the inner tube during coring and overshot retrieval. Each cap is precision CNC-machined from high-strength alloy steel or brass and treated with anti-corrosion coatings to ensure superior durability and wear resistance in demanding drilling environments.

Description

The HQ Inner Tube Cap is manufactured according to international wireline standards (GSZ-H, ISO, and Q-series specifications), ensuring full compatibility and interchangeability with OEM and industry-standard core barrel assemblies. It is also available in BQ, NQ, and PQ sizes, offering a complete solution for different drilling applications.

🔩 Key Features and Specifications

🧱 High-Quality Construction:

Made from premium alloy steel or brass, providing exceptional strength, stability, and longevity under high-torque and pressure conditions.

⚙️ Functional Design:

Acts as the top sealing and retaining component of the inner tube assembly, ensuring tight closure, fluid control, and core protection.

🔧 Compatibility:

Perfectly engineered for HQ wireline core drilling systems and fully interchangeable with other OEM parts in the HQ series.

💧 Leak-Proof Sealing:

Equipped with precision-threaded connections and smooth sealing surfaces to prevent drilling fluid leakage and contamination of core samples.

🛠️ Machining Precision:

CNC precision machining ensures consistent dimensions, thread accuracy, and flawless assembly with inner tube components.

📏 Surface Treatment:

Treated with zinc, phosphate, or nickel coatings for corrosion resistance and improved performance in abrasive drilling environments.

📐 Standard Compliance:

Manufactured to GSZ-H and ISO wireline drilling standards for global compatibility.

📋 Technical Specifications

| Feature | Description |

|---|---|

| Product Name | HQ Inner Tube Cap |

| Function | Seals and protects the top end of the inner tube assembly |

| Series | HQ Wireline Core Drilling |

| Material | Alloy Steel / Brass |

| Hardness (Steel) | 45–50 HRC |

| Surface Finish | Zinc / Nickel / Phosphate Coated |

| Machining | CNC Precision Machined |

| Compatibility | HQ (available in BQ, NQ, PQ) |

| Applications | Core Drilling, Mineral Exploration, Geotechnical Sampling |

💪 Key Benefits

-

✅ Provides secure sealing and prevents contamination during core drilling

-

✅ Maintains pressure balance and ensures efficient fluid circulation

-

✅ Ensures accurate alignment and smooth operation of the inner tube assembly

-

✅ Designed for durability and long service life under high-stress conditions

-

✅ Fully compatible with standard HQ wireline core barrel assemblies

-

✅ Easy to install, replace, and maintain on-site

-

✅ Available in BQ, NQ, HQ, PQ models for full system coverage

🧱 Applications

-

⛏️ Diamond Core Drilling – Used in exploration and mining for core recovery

-

🌍 Geotechnical Drilling – For rock and soil core extraction in infrastructure projects

-

🏗️ Civil and Construction Projects – Supports structural testing and ground sampling

-

💧 Hydrogeological Exploration – Aids in groundwater and aquifer investigations

-

🪓 Mining Operations – Essential for consistent, contamination-free core retrieval