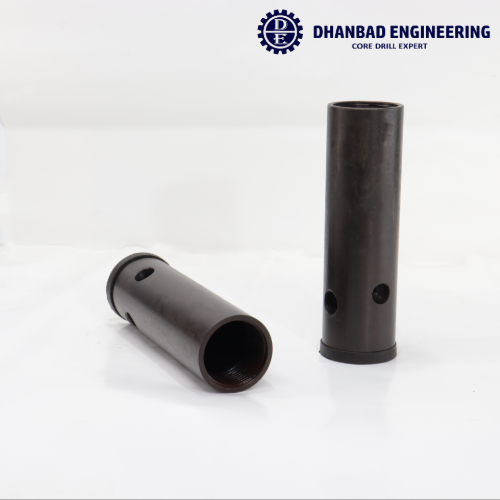

NQ INNER TUBE CAP

NQ Inner Tube Cap – Precision Top End Protection for Wireline Core Barrel Systems

The NQ Inner Tube Cap is a critical upper-end component of the wireline inner tube assembly, designed to secure and protect the inner tube during core drilling operations. It ensures accurate alignment of internal components, maintains pressure balance, and prevents fluid or debris ingress into the inner tube during drilling and retrieval cycles.

Description

Manufactured from high-strength, heat-treated alloy steel or premium-grade brass, the NQ Inner Tube Cap is engineered with tight machining tolerances to deliver perfect fit and long service life under demanding drilling conditions. Its robust construction provides reliable sealing and mechanical strength, ensuring consistent core recovery and minimal downtime for drilling operators.

The NQ Inner Tube Cap is fully compatible with NQ wireline core barrel systems and is also available in BQ, HQ, and PQ sizes to suit a variety of core drilling applications. Designed to meet international GSZ-N and ISO wireline standards, this component guarantees seamless interchangeability with OEM drilling systems and accessories.

🔩 Key Features and Specifications

🧱 Construction:

Made from high-quality alloy steel or brass, CNC-machined, and precision-threaded to ensure perfect assembly with the NQ inner tube body.

⚙️ Function:

Serves as the top closure component for the inner tube, maintaining internal alignment and sealing during core retrieval.

🔧 Compatibility:

Designed specifically for NQ wireline drilling systems, with versions available for BQ, HQ, and PQ configurations.

💧 Sealing Performance:

Engineered with precision-sealed threads and surfaces to prevent drilling fluid or debris contamination inside the inner tube.

🛠️ Surface Treatment:

Finished with anti-corrosion coatings (zinc, phosphate, or nickel plating) to resist oxidation and wear in harsh drilling environments.

📏 Standards Compliance:

Manufactured according to GSZ-N and ISO core drilling specifications, ensuring consistent quality and fit.

📋 Technical Specifications

| Feature | Description |

|---|---|

| Product Name | NQ Inner Tube Cap |

| Function | Seals and protects upper end of inner tube assembly |

| Series | NQ Wireline Core Drilling System |

| Material | Alloy Steel / Brass |

| Surface Finish | Zinc / Nickel Plated Anti-Corrosion Finish |

| Machining | CNC Precision Machined |

| Hardness | 45–50 HRC (for steel version) |

| Compatibility | NQ (also available in BQ, HQ, PQ) |

| Applications | Mineral Exploration, Geotechnical Drilling, Core Sampling |

💪 Key Benefits

-

✅ Provides secure top-end sealing for the inner tube assembly

-

✅ Ensures accurate alignment of core barrel components

-

✅ Prevents contamination of the core sample and inner tube

-

✅ Durable construction for long operational life

-

✅ Compatible with standard NQ wireline core barrels

-

✅ Reduces maintenance and downtime during drilling operations

-

✅ Available in multiple material options to suit site conditions

🧱 Applications

-

⛏️ Diamond Core Drilling – For mineral and ore exploration projects

-

🌍 Geotechnical Drilling – Soil and rock sample extraction

-

🏗️ Construction and Civil Engineering – Borehole testing and sampling

-

💧 Hydrogeological Exploration – Groundwater and aquifer drilling operations

-

🪓 Mining Operations – Core recovery in hard rock formations